Archive for the ‘oil’ Tag

Had my hands in a couple of motors last week. An early XS1 that, judging from the bearing seats, has had as hard a life as Keith Richards face. An XS-D that looks pretty clean inside. Both had what look like original filters.

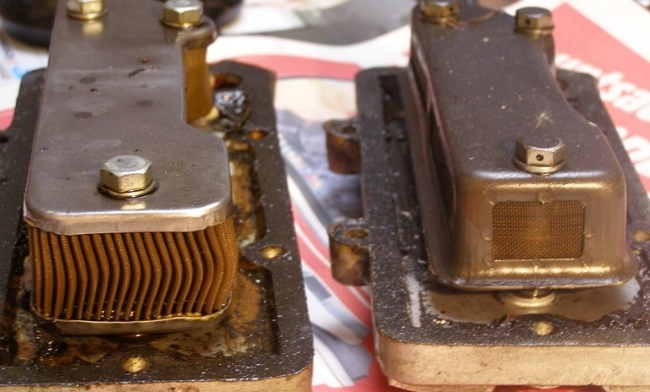

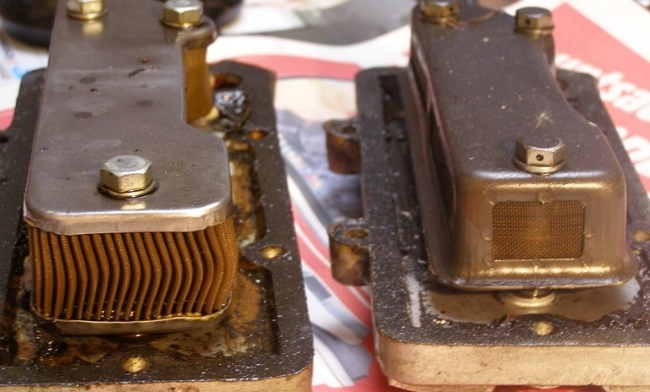

Top: XS-D .. Bottom: XS1 – both showed damage from over-tightening the screws.

Neither gasket had been pre-treated before installation. An SF hammer was required. The gaskets did separate. In half.

Early filter left with full metal jacket. Right: pleated mesh with magnet, right-hand end slightly crushed. Mesh on both sides intact.

Rear: Early filter has no magnets. Mesh is only spot-welded. Later filter has magnets both sides. Mesh is fully cemented. Much more surface area. Mesh is finer.

Early oil flow problems? Filtration issues? Strange the prone corner was never properly reinforced.

Left ends intact.

Fronts. XS1 filter, mesh has started to separate at the spot-welds.

Although I’ve seen much worse both these motors could have benefited from a few more oil changes.

Was pleasantly surprised to see the original XS1 filter here. And that it had survived so much punishment for so long before giving out.

Both engines have obviously been warmed up slowly-the ends are still intact. The mesh separation on the early filter probably derives from crankshaft rotation – from the look of the bearing seats this motor has sung – full throat – louder than Sleazy Joe.

(143.2dB in Hassleholm, Sweden, 2008)

The XS-D filter could make a good emergency reserve. After fitting an end protector. And rechecking each oil change.

Take care of your engines and they will take care of you. These are very much ladies.

If you have ended here and not where you want to go – VOU HAVE A VIRUS ON YOUR COMPUTER … do us both a favour and scroll back to my blog post Virus. Please read this then do a search as suggested.

Yamaha Troubleshooting Manual

In 3 languages. English. French. German

Troubleshooting Manual

Yamaha Troubleshooting Manual

Trouble Shooting

– hopefully this can prove organic … comments and suggestions – correcting, extending

– an engine is basically an air pump – 4 stroke … suck, squeeze, bang, blow

– add fuel, timing and spark = internal combustion engine

– break this system anywhere and you wont get much action

– so your engine turns over ? wont start

– what have you done ? what have you changed, altered, played with, unfixed ?

– air ? fuel ? spark ? …all in the correct ammount and moment ?

– don’t panic…turn the key and petcock/s off, step back …take a breath-deep, go do something you really enjoy for a couple of minutes…

- fuses ? kill switch ?

- battery ? 12.6 V ? put it on charge, brushes ? check charging system

- power to coil/s ? points spark ? plugs ?

- filters ?

- fuel to carbs ? bowls ? cylinders ? floods ?

- compression ? leak-down test ?

·

- adjust your cam chain … can readjust warm once you get her running

- set your tappets

- set your points if you have them .. plugs

– once you get this far she should be at least spitting and farting enough to attempt setting your carbs …

- if she wont idle, look for air leaks ? atu ? massage her pilot jet circuits

- once you can get idle, do the idle speed screw/pilot air screw dance

- smooth transition through to full throttle ?

- synchronise

Electric Troubleshooting

Carburetor Troubleshooting

Starting System Troubleshooting

Engine Troubleshooting

Oil Troubleshooting

Clutch and Gearbox Troubleshooting

Frame Troubleshooting

You must be logged in to post a comment.