I was sitting with the CEO of my local bank the other day. In his office. Watching the falling snow cover my bike. Drinking his coffee. Wondering why I hadn’t put the Trials grip tyres on. Discussing Special Interest Groups. And Corporate and Personal Strategy. Touching upon social responsibilty. Normally a topic dear to my heart. We have thrashed it previously. Several times.

My mind started to wander. I began to visualise. In corporate Manga style. A late ‘60’s Yamaha Emergency Board Meeting. Deep in the wee hours. They had acquired and developed, alone or occasionally in partnership, the technology and knowledge to create and put into production the XS1. Their first real foray into 4 stroke motorcycles. They knew they had a solid motor. The animated Board was trying to decide whether the engine was too strong. Too reliable. Too solid. After all, if it didn’t break down, how would they recover their research, development and acquisition costs? How would their fledgling dealer network cover it’s running costs?

What could they do?

A pimply recent graduate bean counter, no passion for bikes, and a little mechanical understanding-isn’t it interesting how although a lot of knowledge is bad, a little is downright dangerous-pipes up. Squeaky. Insecure.

‘If oil is blood, you could deoptimise the circulation of it and induce mechanical wear’.

Planned obsolescence. The cascading effect?

The more units you sell the more work you create. Not only do you have a captive service market you monopolise parts. Henry rolls over and grumbles into his cobweb

‘Those Japanese couldn’t invent anything if they tried.’

And so the infamous XS650 Oil Sieve was created.

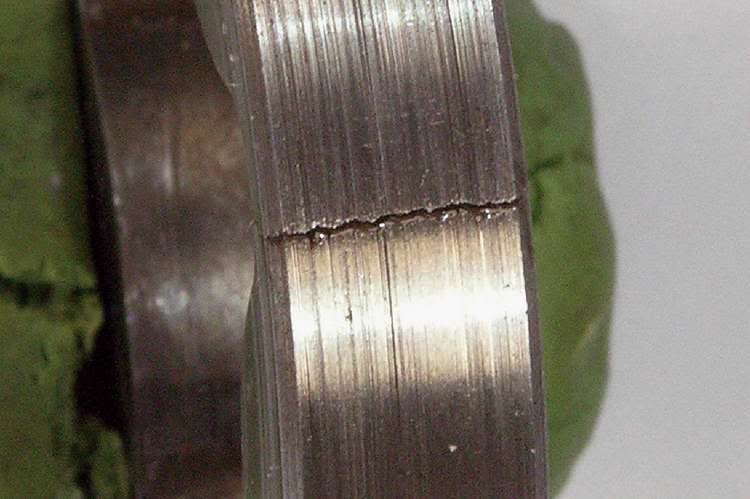

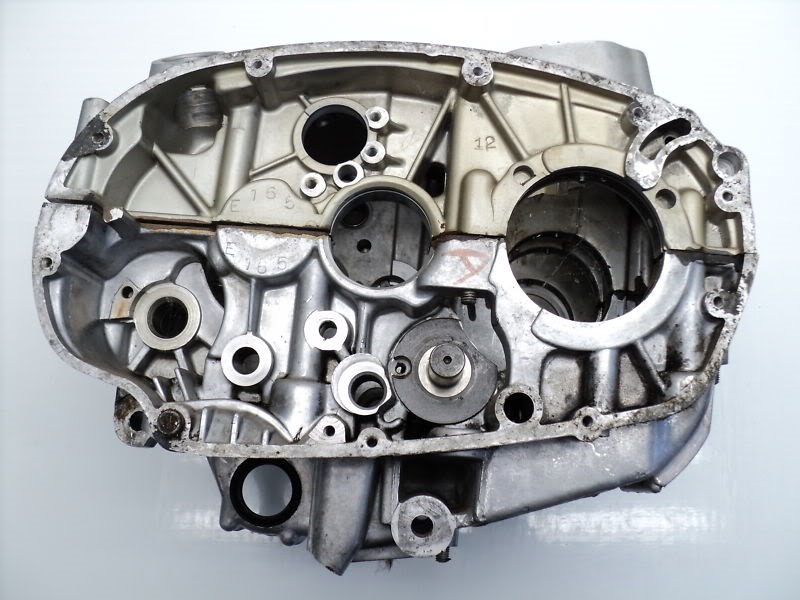

unprotected, strong flows esp when cold rupture this pdq

Simple really.

- Expose the weakest point, and

- Use mesh too coarse to remove the metal pieces shed by the gears.

repaired and protected by a copper cover … will be soldered together too

The Sieve sits at the lowest point giving a rough treatment to the ‘suction’ side-about 0.9 Bar or 13.5 PSI-of the pump. Any foreign material breaching it goes directly to the pump. Na great.

with corresponding wear

and breakage

and subsequent loading of the filter … broken primary springs found in the sump

the bypass valve, doubles as the filter bolt … a safety feature only … activates with about 14 psi pressure difference across the filter … at 21mm you may be tempted to tighten this down. DON’T.

Original engines had a bypass valve in the ‘push-side’ filter and a Pressure Release Valve in the pump itself.

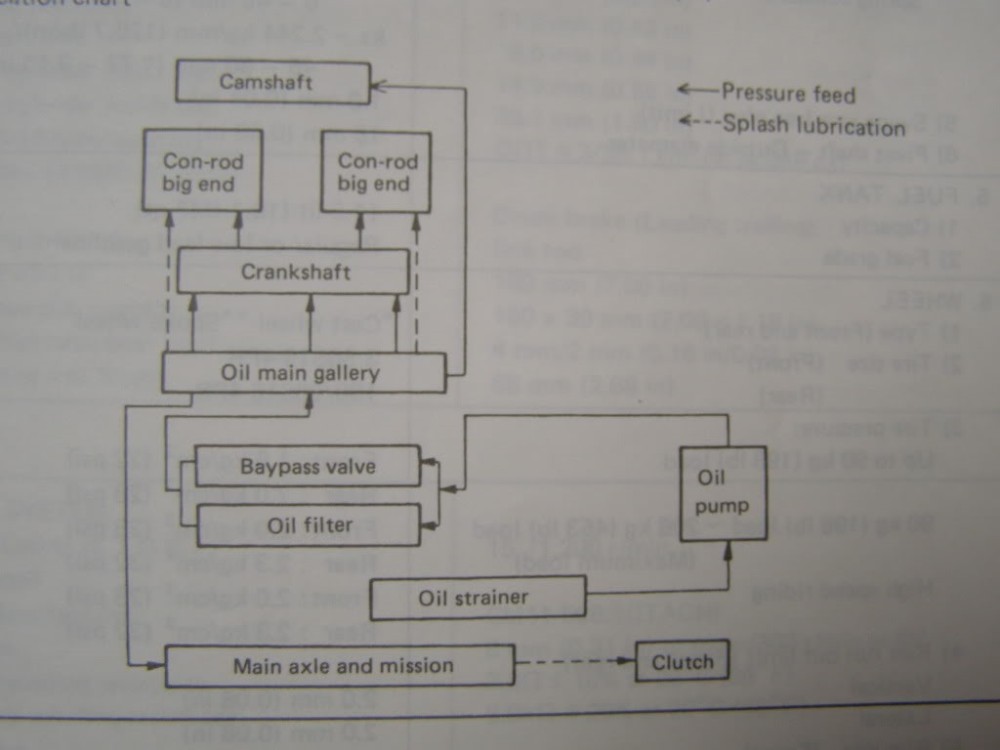

oil circuit … shows direct and splash contact

early pump with prv … was it a good idea to remove it?

This is the text from the original manual for the early XS with PRV on the oil pump:

- ‘the oil pump is fitted with a bypass valve-check ball and spring-that permits the oil from the pump to be redirected back to the oil reservoir in case of excessive pressure in the delivery passages…the cover has a drilled hole that leads to a pressure relief check ball. If too much pressure develops the check ball releases oil back into the crankcase’

and:

- ‘the filter is fitted with a bypass. If the filter is plugged, oil is forced through a spring-loaded ball type check valve in the locking bolt and into the engine delivery passage. In this manner, oil delivery to the engine will not be stopped by a clogged filter.’

The beancounter spat the dummy. The pump PRV was quickly axed, reducing costs and unfiltered pumped oil bypasses the filter if blocked. If the owner isn’t prepared to maintain his bike dirty oil is better than none at all. A concession in favour of goodwill.

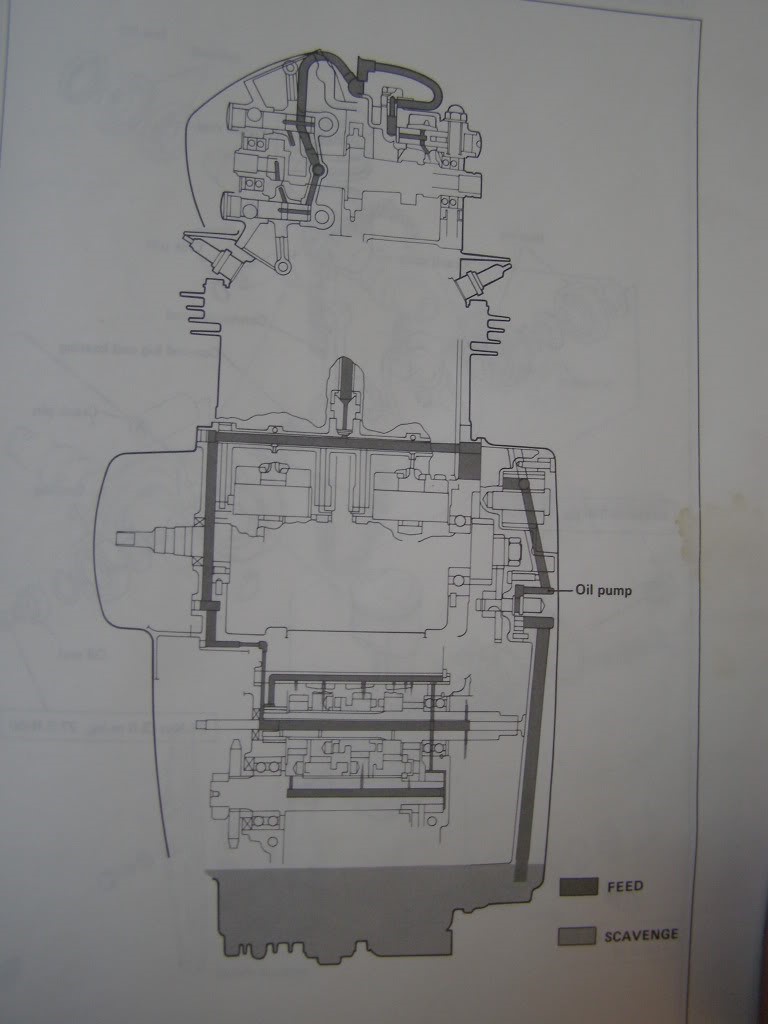

oil circuit

more oil

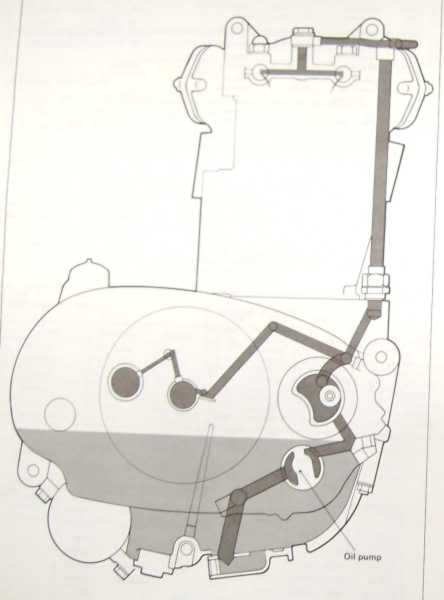

passes the sieve and through this hole

and out here at the base from the hole under the crank into the side cover below … then back into the upper casing-1 o’clock

into the right engine cover to the pump then the filter and back out the top there to …

Reducer … 14×1.5 … use 2x22mm spanners when working this or you will break the pipe

you will need one of these … 16 x 1.5mm, Öl024 from Twins-inn … stainless steel … if you over-tighten

leads from the reducer to the head and rocker gear

transverse gallery feeds crank mains and has a jet each side to spray oil onto the big ends … also see the holes to feed the transmission, shift fork and drive shafts

256 306 and447 conrods were slotted

533 big ends were not slotted and have scooped pins

and through this passage over the crank to the transmission shaft and shift mechanism

and into the transmission shaft where it feeds the gears, the selectors and then the drive shaft

oil fed from notch seen to the right … selectors also mist fed

These old girls run hot. Vibrators will do that for you. Do yourselves a big favour. Think lubrication. Lots of it. Regularly applied. Every 1500km is good.

lubrication is GOOD

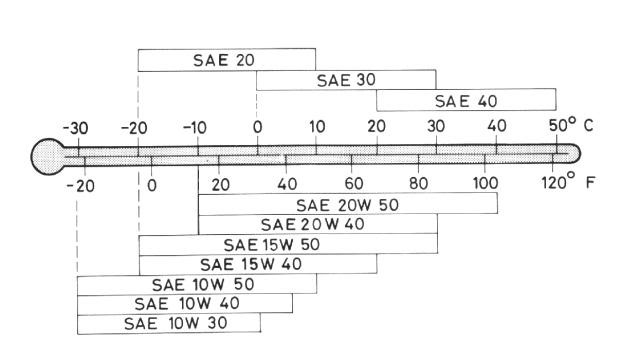

Motorcycle oils. Keep those modifiers to a minimum. Yamaha recommend SAE 20-40.

temp-oil specs

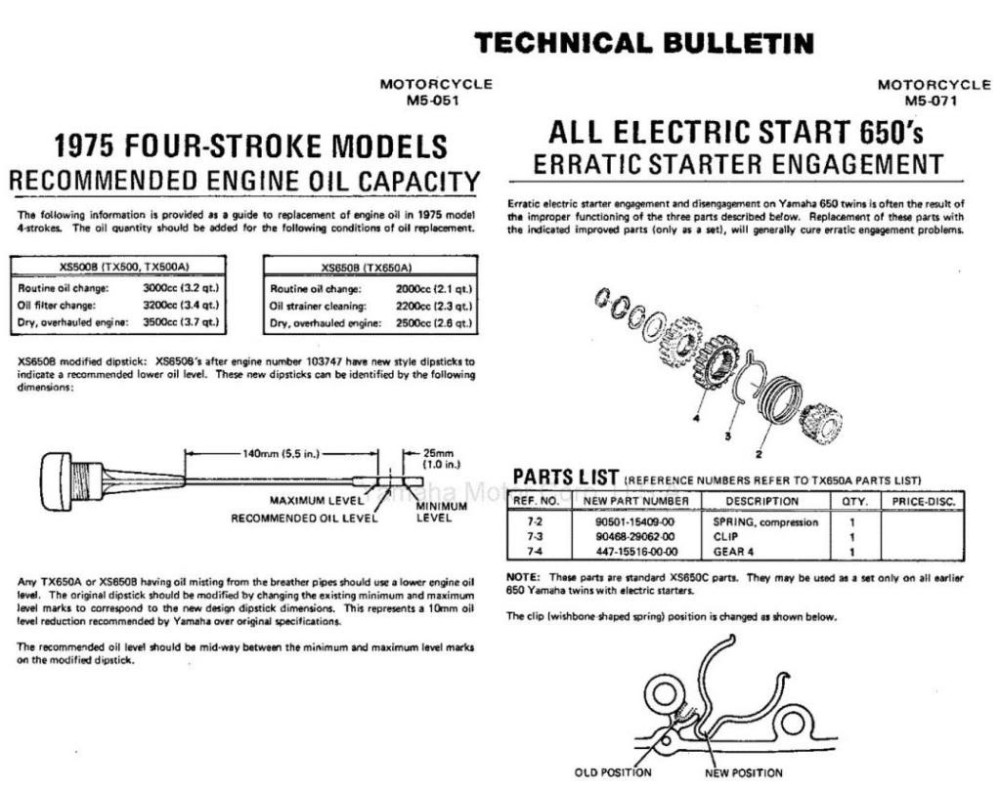

tech bulletin … oil dipstick

Note, when running a tacho remember it is driven directly off the oil pump … if your tacho stops working, check out why immediately, your oil pump may also not be working

This string is loaded with good stuff. Thanks.

I have a question about oil…synthetic oil for my ’81 650..good idea? …bad idea?.I’ve been told synthetic oil will destroy the clutch plates and/or cause clutch slippage…also been told using synthetic oil will increase engine longevity. Also been told if it is a bad idea to have used synthetic (I just put a 20/50 combination oil/synthetic in about 50 miles ago with hno problems so far, and I used synthetic only for years in my shovelhead Harley with no probs) that now I should drain & replace with regular oil, run till its hot and drain and replace 6 times. So, I’m a bit stumped. Any sound a;dvice would be appreciated.

Charlie

Charlie, I have literally seen good mates almost come to blows over this issue.

Synthetic oils were originally developed for aircraft use if I remember correctly. They reduce friction and wear while functioning at hot/cold temperature extremes and withstand hard and long engine operation with less viscocity breakdown. They tend to be thin and slippery. With older motors there may be seal swell issues.

One of the main problems is that many motorcycle engines share their oil with the transmission and clutch so you need to be aware of exactly which friction modifiers are included in any oil used. Slipping clutches are the result.

I dont really want to join this arguement and certainly will not endorse any particular oil. However I generally use a low detergent heavy duty mineral oil with an SL rating. I tend to be careful about zinc and molbdynum additives which although they provide added wear protection are themselves friction modifiers and can affect the clutch.

Because mineral oils generally show faster viscocity breakdown I change my oil regularly.

I do occassionally fill my bikes wih a synthetic-mineral blend for short distances simply to give the internals a good clean. After draining I tie the clutch lever to the handlebar overnight to allow the clutch plates to ‘drip dry’ before refilling with my favourite mineral oil. I have never had any problems by doing this.

An interesting short discussion on this can be found at .http://vfrworld.com/tex_vfr/tech/oil.htm