Archive for the ‘M – Engine’ Category

Been building myself a couple of XS motors lately. 277° and 360°. Have had the blocks together for some time – gearbox and crank, new bearings and seals etc.

Got round to stripping down an old XS1 head the other day. Just to check her out. Actually not too bad, some leakage around the top of the inlet valves, guides ok, valve stems straight. Cam ok. Rockers starting to wear a little. Decided to replace them and the shafts as I had a new set lying around and I have a new cam.

First you need to remove the 4 press fit sleeves that seal the outer-headstuds. You can simply bash these out but I wanted to remove the rockers and the shafts sit pretty tight (unlike the SR500) so I popped the rockerbox in the oven for a while.

The sleeves knock out easily with an 8mm socket.

Then you can get to the rocker shafts. These are tight.The puller I had rustled up for the SR500 wasnt up for the job but still had the longest 6mm thread I had on hand so I simply packed the outside with a socket and an old gearbox bearing and wound the shafts out.

Total time, less than 5 minutes once heated (if you heat use the oven and not a torch – no point in risking warping the box).

Slapped her back into the oven for a few minutes before inserting the new shafts and rockers. Dont forget to blow out the oil galleries first, and lube.

If wanting to reuse remember to bag and label: left/right, inlet/outlet

enjoy

Had my hands in a couple of motors last week. An early XS1 that, judging from the bearing seats, has had as hard a life as Keith Richards face. An XS-D that looks pretty clean inside. Both had what look like original filters.

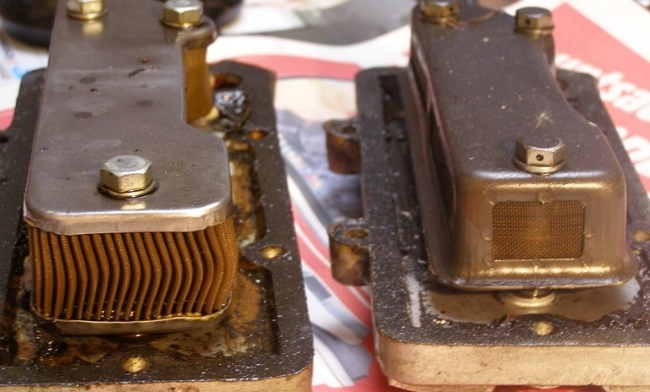

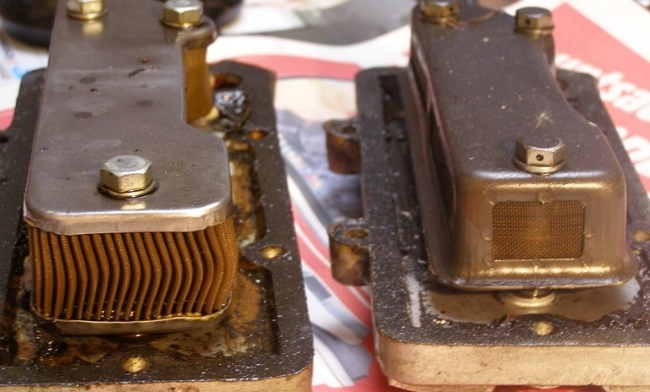

Top: XS-D .. Bottom: XS1 – both showed damage from over-tightening the screws.

Neither gasket had been pre-treated before installation. An SF hammer was required. The gaskets did separate. In half.

Early filter left with full metal jacket. Right: pleated mesh with magnet, right-hand end slightly crushed. Mesh on both sides intact.

Rear: Early filter has no magnets. Mesh is only spot-welded. Later filter has magnets both sides. Mesh is fully cemented. Much more surface area. Mesh is finer.

Early oil flow problems? Filtration issues? Strange the prone corner was never properly reinforced.

Left ends intact.

Fronts. XS1 filter, mesh has started to separate at the spot-welds.

Although I’ve seen much worse both these motors could have benefited from a few more oil changes.

Was pleasantly surprised to see the original XS1 filter here. And that it had survived so much punishment for so long before giving out.

Both engines have obviously been warmed up slowly-the ends are still intact. The mesh separation on the early filter probably derives from crankshaft rotation – from the look of the bearing seats this motor has sung – full throat – louder than Sleazy Joe.

(143.2dB in Hassleholm, Sweden, 2008)

The XS-D filter could make a good emergency reserve. After fitting an end protector. And rechecking each oil change.

Take care of your engines and they will take care of you. These are very much ladies.

You must be logged in to post a comment.