Once upon a time I had this nice little SR500.

my 48T SR500

I got it into my head to build a sidecar – to take my son to school. Started collecting bits. And ideas. (I did consider using the XS650. Decided against it as the SR and the Velorex match pretty well. Both light and manouverable.)

making a start … leading link forks, box section swingarm and front disc brake … ended up reworking the forks – added an extra 1cm castor (nachlauf)

Got hold of a Velorex 562 sidecar. How to connect? Collected a lot of ideas.

- Original Velorex frame clamps. Too much point load on the frame. And they work loose.

- Mount points welded directly to frame. Weakens frame. Point loading.

- Subframe. Bolts directly to frame. Sidecar mounted to subframe. Load distributed. Solid.

Sounded good to me. What about TÜV (MOT) certification? Could make my own subframe but I’m not a ticketed welder. Visited my local friendly greycoat (TÜVler). Fixed his brown-eye on me and shat on my ideas. Some people simply have no imagination. No sense of adventure.

Found a list of Gespannbauers (sidecar builders). Rang around. Karl Schmid from Mickhausen near Augsburg was the most approachable, and fitted into my time frame. So, off I went. Beginning of September. Said he would try to have it ready by the end of the month. OK by me. Spent the next week constructing at Automechanika – Automobile industry Trade Fair. Stand handover Monday. Home late. Phone rings 08.00 Tuesday morning “TÜV is on Friday. You can pick it up then.” Hang-on? It’s not even midmonth! I’m not ready! Cant believe it’s early. Kool!!

Commitments, illness, work, rugby meant I wasn’t able to get down there for a week. Got a train ticket, €39 to Schwabmünchen. Left Frankfurt at 05.30. 20 minutes late. By Stuttgart the train was getting pretty full. Ah, yes, 1st day of Oktoberfest. God I love girls in Dirndls. Nothing quite like it. Eye candy.

Was picked-up at the station. Sweet.

finally there

half workshop half house … nice

Smells just like a metal workshop should.

Karl Schmid – Gespannbauer

there she is … waiting

Took my time getting home. 650km. The first 3 hours in driving rain. Forgot to switch back from reserve and ran out of gas in the middle of nowhere. Great way to meet friendly strangers. Took the sideroads. No map. Using the sun position – when I could see it. And geography. Had a great day. Perfect way to meet my new toy. Glad I took 3 pairs of riding gloves. Meant dry warm hands. Mostly. Uses more gas, be careful cornering, no need to put your foot down when stopped.

front on

rhs … the boat is sitting on the original frame podests … it is possible to rework these and lower the body 30-40 mm … lower centre of gravity

you can see the body mount podests on this frame

as a reference: this velorex frame has been heavily modified – cross bracing, lowered body mounts, bolt on lower frame mount points, extended rear, self-made shock tower, self-made extended swingarm

lhs … have some longer konis I may swap into the forks – lift the front a little

324mm konis up front, from my guzzi … replace the series SR shock 316mm … feels better

connected – front view … exhaust pipe is very close to the lower car mount – i have now ground the mount to give more free space for the pipe

connected – rear view … the lower rear sidecar mount, seen here has been shifted to the rear of the sidecar to leave space to kickstart … the upper rear mount is just on the limit of being restrictive, my boot heel hits the bar if Im not careful

front – upper … boxed over the frame

rear upper, subframe fixed to the shock mount, sidecar mounted off the subframe

rear upper, subframe fixed to the shock mount, sidecar mounted off the subframe … you can see the lower sidecar mount point going off to the left … rear lower subframe mount uses the footpeg mounting points (will take photos of these and post as well)

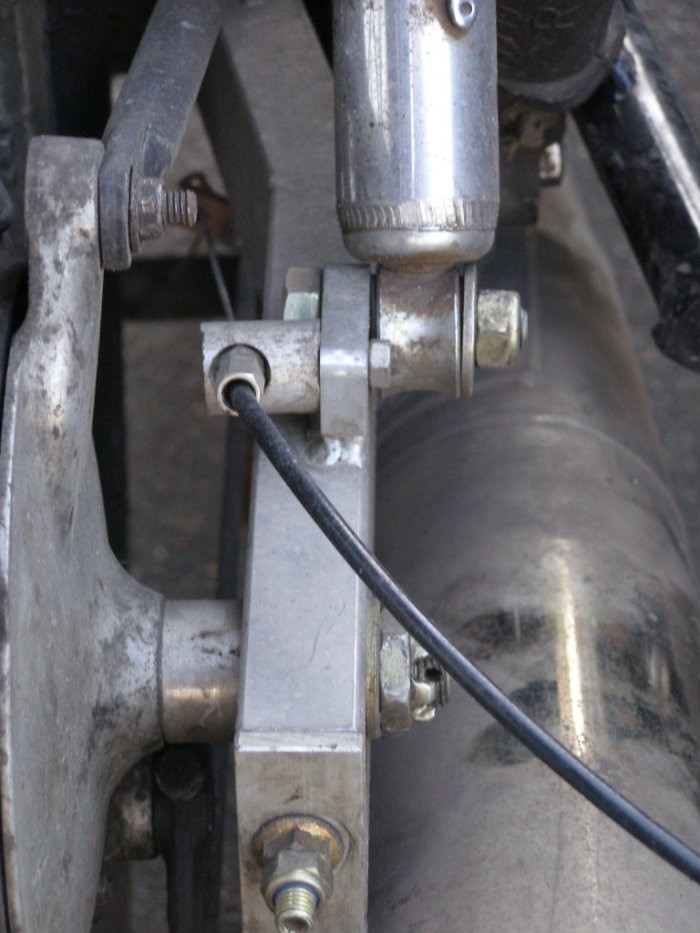

sidecar brake cable … attached to footbrake rod – pulls against the alu block

nice bonus – the front lower sidecar mount serves as a perfect footrest – very comfortable riding – need to practice braking with my heel

Fully certified (TÜV)!!

Now I’m ready to take my 6yo son to school.

off to school

I’ve now ridden this a couple of thousand km. Not bad for a month.

- Have added a longer set of shocks to the forks-a bit more height (not too much)-needed to alter the sidecar settings slightly.

- The rear shocks are far too weak. Tried a set of SR500 konis – still too weak. Looking for a better solution.

- In retrospect I might design the subframe somewhat differently. As a 1 piece there is structural integrity and load-spread across the whole frame but the thing will need to be removed to repair things like clutch, kickstart, oil pump. A 2 piece subframe, although loading the front and rear of the frame separately allows access to the right hand case. Just how strong is the original frame?

- I will add a rollbar and 4 point seatbelt.

- Am glad I didn’t use the XS650. The Velorex is light and flies easily. Great for freaking out cagers that follow too close.

- Had forgotten just how physical sidecar riding is. Body position is critical when racing through corners. My 6 yo son is becoming a good monkey.

Couple of updates …

VM32SS carb from an early XT500, rejetted … large increase in torque for minor loss of top speed (-10kmh max.) … purrfect fit … have ordered a new boot

Have exchanged the carb. Taken the BST34 flat slide out. Put a VM32SS round slide from an early XT500 in. Direct fit. Mates to both the carb boot and air filter

no problem.

Starting point : 41mm single wall head pipe … K & N filter insert, open carb boot.

- Pilot Jet 25

- Main Jet 260

- Needle Clip position #4

- Float at 21mm (float was twisted-one side sat higher than the other)

- Cables are different, (both 2 cable system) … shortened the BST push cable outer and used it as a VM pull cable, added a second nut to give myself adjustment at both the carb and handlebar.

I love the difference. Not quite as much top speed (I rarely travel more than 100-105kmh anyway) BUT there is a noticeable increase in torque from idle. Pulls great through the complete rev range. Fuel consumption is better too.

Exchanged the std Velorex lights for LEDs. Figured it would be easier on the batteryless electrics I run. Had halogen blinkers on the left hand side. Load-independant blinker relay. Seems to work with halogen front and LED rear but not halogen left and LED right. Appears to require the same combined load on both sides. Swapped the halogens for LEDs and all was well. Except for the headlight the bike now has LEDs all round.

LED rear

and LED front

Have booked the bike in to have the subframe modified. Never liked the front top mount – headstock. Transfers the stress directly to a known weak point. The square section tube under the oil tank. Cracks along the weld – both sides.

subframe top monut, front … at headstock … clamped to known weak point – leads to cracking along the welds

Had a front brace made up. Clamps to the frame. Bolted up through the steering head – 2 bearings keep the steering operating. Brace back to the subframe.

brace

front brace – rhs – showing link to subframe – note, this is all easily removeable, clamp releases, link unbolts from brace, brace separates from bearing house

my other three-wheeler … shop hack … sharing space with the XS

A common SR500 rear wheel problem is the wearing out of the rear sprocket carrier. If this isnt regularly greased via the provided grease nipple the wear accelerates. Result? Sloppy rear wheel. The added stresses imparted by running a sidecar exacerbates this problem.

This can be rectified by machining the carrier ID to fit 1 or 2 bearings and reducing the existing stem in the hub. I tried contacting an SR500 forum member here in Germany but he never replied. A pity as he provided a nice 2 bearing modification. While looking for a solution I found complete a rear wheel, already modified, on fleabay. New bearings, brake shoes, carrier dampening rubbers. For cheaper than used wheels usually go for. Score!

complete rear wheel – already modified – single carrier bearing and reducing spacer

rear sprocket carrier – machined to fit a bearing – reducing spacer fitted – i have covered this with the plastic cover found on XT500s – lube as normal using the grease nipple provided

rear view of sprocket carrier – can see both the bearing and reducing spacer … fits as normal to the hub

You must be logged in to post a comment.